The cost of shaker screens means the quality in some degree. And besides that, cost means service quality, too. Why do we talk about the quality and cost relation again and again? We always face questions from clients " Why is the price of your screen higher than others' "

Price of Aipu Shaker Screen

Frankly speaking, our screens price is reasonable and cost-effective. We make screen panels with high quality raw material from reliable and stable suppliers. For example, the wire mesh material stainless steel wire. Although the suppliers or manufacturers tell theirs are high quality S.S304 when you check the mill test or quality certificate you'll find something on the percentage of main content, such as Ni, Cr, and so on

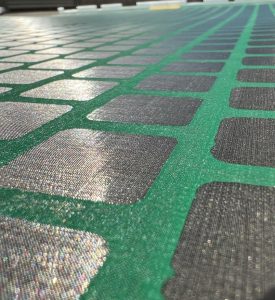

Besides the difference of content, the opening of screen cloth and the wire diameter affect quality, too. Some wire mesh manufacturers wave screens with even wire with good content features, while some use materials at a lower grade quality. Finally, the screen surface reflects the difference.

Price of Aipu shaker screen is from USD50 to USD140, these are the panels used on shale shakers for oil and gas drilling mud solids control. Different price is because of different model number or screen panel size. For example, the soft hook strap screen is at price about USD50, while corrugated screen panel for HYP shaker is about USD120. Moreover, the price of flat panel is USD90, while the corrugated panel is about USD110 for the same model and same mesh size screen.

Prices of screens made by other suppliers

In China, there are tens of manufacturers making shaker screens. Yes, a hundred suppliers will quote a hundred prices. Why are there different levels? And the difference even up to 50%. For example, our soft hook strap screen is USD60 while others may quote USD30; the composite framed screen is USD90 while others quote USD60.

The difference is among appearance/surface, raw material, package, services and so on. In the materials, there are wire mesh, supporting layer, internal frame tube and so on.

Let's take the composite framed screens as an example. We use plastic powder, fibreglass, carbon and colour powder as the composite injection material. And use the national standard carbon steel tube & steel bar to weld internal supporting frame. Then we inject the materials on the steel frames.

Difference is from different plastic, carbon, steel, tehcnique, and the manufacture procedure, as well as machine capability. These will all affect frame quality and then the whole screen panel quality.

At the same time, some suppliers pack screens in think cartons and put them on the pallets or wihout pallets to save cost. Aipu pack screens as cartons inside plywood case outside or plywood pallets outside wrapped with film. We'll pack them according to clients' requirements and shipment methods.

Yes, the final cost and price are very different then.

How to get the screens priced reasonably?

Kindly suggest buyers and users seeking professional suppliers. They should be in oil and gas industry, professional in shaker screens, well drilling mud equipment and related products. Because they will always face different demand from different customers. They have sufficient experience of different working conditions can provide optimal solutions to a certain job site.

Asking some different suppliers the price of shaker screens; asking them for detail technical specification, inquiring them to provide the samples. When you receive the samples, check all panels on appearance including packages, surface, back strip(if there is). Then you'll remove some poor quality panels. Finally, install screens on shaker to check their performance. Please pay attention here, not only consider the screens life but also the screen filtration efficiency and separation accuracy, also general mud cost saved.

Considering all above issues then confirm if the screens are cost-effective. You'll get the objective answer and optimal solutions

Please leave comments below or contact us freely if you have any demands or questions