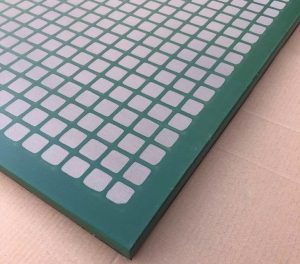

Screen cloth is the raw material of shaker screen panel. They are wire mesh woven by S.S wire. One screen panel is made from 2/3 layers wire mesh. The wire meshes are holding different wire diameter and mesh size or hole size

Screen cloth information

Screen cloth here means the single layer of wire mesh cut well for shaker screen panel. Usually, mesh size is ranged from 18 mesh to 325 mesh. And the wire diameter is ranged from 0.009 to 0.0011 inch. The screen cloth including plain woven and the twill woven one. And the same mesh size can be woven with different wire. The difference is the hole size or opening

Screen clothes quality will impact shaker screen panel much. If the mesh and surface was not even, the separation point will vary even for same mesh size screen. Then API size will be not accurate enough. Furthermore, the screen surface and performance will be impacted because of coarse manufacture or technique.

Difference between screen cloth and shaker screens

Shaker screens are made from multiple-layer screen cloths. So, the cut point or the separation point should be based on complete panel or the combination of 3 layer cloth. Top layer/finest layer can not tell the actual separation point although it is the separation layer.

As we know, 3 layers combined together, there must be cross hole and wire among layers. That will certainly affect whole screen panel separation result

We won't use one single layer cloth to be shaker screen fit on shale shaker deck. And during the operation, the drilling fluids will stay on wire to narrow the hole. But not too much, so will stay in cut point range requested by certain API designation

How to get exact value on screen cloth and shaker screen

Test the screen cloth prior to making shaker screen by computer. It will give us a relatively accurate data. We also can measure the cloth by hand with microscope, that will be a bit higher tolerance than computer digital one

For shaker screens, test the cut point or exact separation point we need special device with powder and special shaking device to get the separation point of screen panel instead of single layer cloth

Please refer to previous articles to get more information on the shaker screen and screen cloth.